Rust-Oleum Rust Reformer Instructions: A Comprehensive Guide

Welcome to your comprehensive guide to using Rust-Oleum Rust Reformer! This guide provides step-by-step instructions and helpful tips for transforming rusted metal surfaces into paintable surfaces. Whether you’re a DIY enthusiast or a professional, this guide will ensure successful application and long-lasting rust protection.

What is Rust-Oleum Rust Reformer?

Rust-Oleum Rust Reformer is a specialized coating designed to combat rust on metal surfaces. This product chemically converts rust into a non-rusting, paintable surface, eliminating the need for extensive sanding or grinding to remove rust completely. It’s available in both spray and brush-on formulations, offering flexibility for various application needs.

The Rust Reformer works by bonding with the existing rust, transforming it into a stable, paint-ready layer. This process not only stops the rust from spreading but also provides a protective barrier against future corrosion. The resulting surface is a flat black finish that serves as an excellent primer for subsequent topcoats.

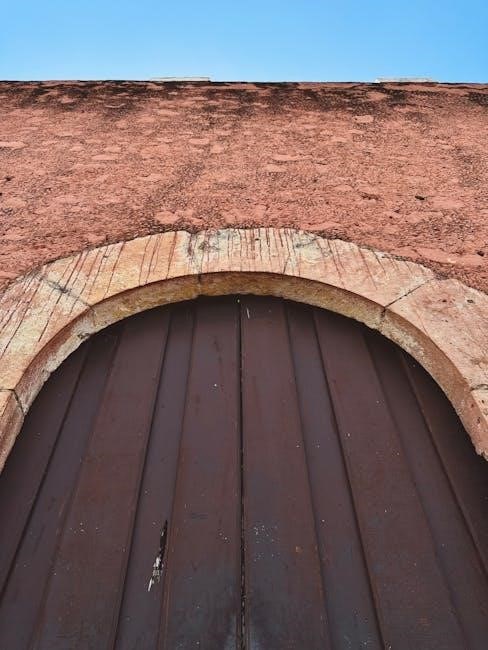

Ideal for both indoor and outdoor use, Rust-Oleum Rust Reformer is perfect for restoring rusted metal on cars, fences, railings, and other metal structures. Its ease of use and effective rust conversion make it a popular choice for DIYers and professionals looking for a reliable solution to rust problems. By chemically altering the rust, it creates a durable base for paint, ensuring long-lasting protection and a professional finish. Essentially, it transforms a problem into a primed surface.

Key Features and Benefits of Rust-Oleum Rust Reformer

Rust-Oleum Rust Reformer boasts several key features and benefits that make it a standout product for rust treatment. Primarily, it chemically converts rust into a paintable, non-rusting surface, saving significant time and effort by eliminating the need for extensive sanding down to bare metal. This feature is particularly valuable for intricate or hard-to-reach areas where manual rust removal is challenging.

Another significant benefit is its ability to prevent future rust. The formula contains rust-preventative technology that inhibits corrosion, ensuring long-lasting protection for metal surfaces. The product dries quickly, typically within 20-40 minutes, allowing for faster project completion. Its durable, corrosion-resistant finish makes it suitable for both indoor and outdoor applications.

Furthermore, Rust-Oleum Rust Reformer is available in both spray and brush-on options, providing versatility for different project requirements. The flat-black finish serves as an excellent primer, ensuring optimal adhesion for topcoats. Its water-based formula allows for easy cleanup with soap and water. By simplifying the rust removal process and offering lasting protection, Rust-Oleum Rust Reformer is an ideal solution for maintaining and restoring metal surfaces.

Surface Preparation Before Application

Proper surface preparation is crucial for achieving optimal results with Rust-Oleum Rust Reformer. Begin by removing any loose rust, scale, and deteriorated coatings using a wire brush, scraper, or power tool. Thoroughly clean the surface to eliminate dirt, grease, oil, and other contaminants that may hinder adhesion. A solvent-based cleaner can be used for this purpose, ensuring a clean and stable base for the reformer.

For heavily rusted surfaces, consider using a more aggressive method such as sanding or grinding to remove as much loose material as possible. However, it’s not necessary to remove all rust down to bare metal, as the Rust Reformer is designed to bond with and convert existing rust. After cleaning, ensure the surface is completely dry before proceeding with the application. Avoid applying the product in windy or dusty conditions to prevent contamination.

Mask off any areas that you don’t want to be coated with the reformer. This step is essential for achieving a clean and professional finish. Remember that Rust-Oleum Rust Reformer is designed for use on rusted metal surfaces only; it should not be applied to galvanized steel or non-rusted metal. Taking the time to properly prepare the surface will significantly enhance the reformer’s performance and longevity.

Application Methods: Brush vs. Spray

Rust-Oleum Rust Reformer offers two primary application methods: brush and spray, each with its own advantages. Brush application allows for precise control, making it ideal for small areas, intricate details, or touch-up work. It ensures thorough coverage, especially on uneven or heavily rusted surfaces. When using a brush, select a high-quality brush suitable for water-based coatings. Pour a small amount of Rust Reformer into a non-metallic container to avoid contaminating the original can.

Spray application, on the other hand, provides a faster and more uniform coating, particularly on larger surfaces. It’s excellent for achieving a smooth finish and reaching tight spaces. Aerosol spray cans are convenient and require minimal cleanup. However, proper ventilation is crucial when spraying. Ensure you are in a well-ventilated area or wearing appropriate respiratory protection.

Ultimately, the choice between brush and spray depends on the project’s size, complexity, and your personal preference. Both methods, when executed correctly, will effectively transform rust into a paintable surface. For optimal results, consider testing both methods on a small, inconspicuous area to determine which works best for your specific application.

Step-by-Step Instructions for Brush Application

Follow these steps for successful brush application of Rust-Oleum Rust Reformer. First, ensure the surface is properly prepared by removing loose rust and debris with a wire brush. Clean the area with a degreaser to eliminate any oil or contaminants. Stir the Rust Reformer thoroughly before use, and pour a small amount into a non-metallic container.

Using a high-quality brush, apply a thin, even coat of Rust Reformer to the rusted surface. Work the product into any pits or crevices for complete coverage. Avoid applying too thickly, as this can lead to drips and uneven drying. Allow the first coat to dry completely, typically around 15 minutes, until a black film forms.

Inspect the surface and apply a second coat if necessary, especially on heavily rusted areas. Ensure each coat is allowed to dry fully before applying the next. Once the final coat is dry, the surface is ready to be painted. For oil-based paints, wait at least 4 hours; for lacquer or aerosol paints, wait 3 days. If no topcoat is desired, a second application of Rust Reformer is recommended for enhanced protection.

Step-by-Step Instructions for Spray Application

Achieving a smooth, even finish with Rust-Oleum Rust Reformer spray requires careful application. Begin by preparing the rusted surface, removing loose rust and scale using a wire brush or power tool. Clean the area thoroughly to remove any dirt, grease, or oil. Ensure the surface is completely dry before proceeding.

Shake the Rust-Oleum Rust Reformer spray can vigorously for at least one minute to ensure proper mixing. Hold the can 6-8 inches away from the surface and apply a light, even coat using a sweeping motion. Overlap each pass slightly to avoid streaks; Avoid applying too heavily in one area, as this can cause runs and drips.

Allow the first coat to dry for approximately 20-40 minutes, or until the surface is no longer tacky. Inspect the coverage and apply a second light coat if needed, especially on heavily rusted areas. Ensure proper ventilation during application and drying. Once the final coat is dry, the surface is ready for painting. For best results, allow 24 hours before applying a topcoat of Rust-Oleum Stops Rust paint for optimal protection.

Drying Time and Curing Process

Understanding the drying time and curing process of Rust-Oleum Rust Reformer is crucial for achieving optimal results and long-lasting protection. The initial drying time for Rust-Oleum Rust Reformer is approximately 15-40 minutes, during which the product transforms the rust into a paintable surface. This timeframe can vary depending on environmental conditions such as temperature and humidity.

For oil-based paints, it is recommended to wait at least 4 hours after the Rust Reformer has dried before applying the topcoat. If you plan to use lacquer or aerosol paints, allow a longer drying time of about 3 days; This extended period ensures that the Rust Reformer is fully cured and will not react negatively with the topcoat.

Complete curing, where the product reaches its maximum hardness and durability, can take up to 7 days under ideal conditions. During this curing phase, avoid exposing the treated surface to harsh chemicals or excessive moisture to ensure the reformer properly bonds with the metal and provides long-term rust prevention. Following these guidelines will help ensure the longevity of the application.

Painting Over Rust-Oleum Rust Reformer

After applying Rust-Oleum Rust Reformer, painting over it enhances the protection and aesthetics of the treated surface. The Rust Reformer transforms rust into a paintable, flat-black surface, providing a solid foundation for subsequent coatings. Before painting, ensure the reformed surface is completely dry and free from any loose particles or contaminants.

For optimal results, consider the type of paint you intend to use. Oil-based paints generally require a waiting period of about 4 hours after the Rust Reformer application. When using lacquer or aerosol paints, it’s best to wait approximately 3 days to ensure the reformer is fully cured and won’t react with the topcoat. Applying a primer before the final coat can further improve adhesion and durability, especially if using a water-based topcoat over the solvent-based Rust Reformer.

Selecting the right paint is crucial. Rust-Oleum Stops Rust paints are highly recommended for their compatibility and enhanced rust prevention properties, ensuring a cohesive and long-lasting finish. Always follow the paint manufacturer’s instructions for application and drying times to achieve the best possible outcome.

Recommended Top Coats for Optimal Protection

Selecting the right top coat after applying Rust-Oleum Rust Reformer is crucial for maximizing protection and achieving the desired finish. For superior rust prevention and durability, Rust-Oleum Stops Rust paints are highly recommended. These paints are specifically formulated to work in conjunction with the Rust Reformer, providing enhanced resistance to corrosion and the elements.

Oil-based top coats are an excellent choice due to their robust protective qualities and compatibility with the reformed surface. Alternatively, for water-based finishes, consider using a solvent-based primer first to ensure proper adhesion and prevent any adverse reactions between the layers. When choosing a top coat, consider the intended use of the item; For automotive applications, Rust-Oleum Automotive paints offer excellent durability and resistance to wear and tear.

Ensure the selected top coat is suitable for both indoor and outdoor use, depending on the project. Always follow the manufacturer’s instructions regarding application techniques, drying times, and safety precautions to achieve the best possible results and long-lasting protection.

Troubleshooting Common Issues

Even with careful application, some issues may arise when using Rust-Oleum Rust Reformer. One common problem is uneven coverage, which can be resolved by applying a second coat, ensuring thorough and consistent application. If the reformer dries with a sticky or tacky finish, it may indicate that the temperature or humidity levels were not within the recommended range during application. Ensure temperatures are between 50-90°F (10-32°C) and humidity is below 85% for optimal drying.

Another issue can be poor adhesion of the top coat. This often occurs if the reformed surface was not properly cleaned or if the top coat is incompatible with the Rust Reformer. Always clean the surface thoroughly before applying the reformer, and select a compatible top coat, such as Rust-Oleum Stops Rust paints.

If the Rust Reformer does not convert the rust to a black, paintable surface, it may indicate that the rust layer was too thick. Remove any loose rust with a wire brush before application. For best results, follow the recommended drying times before applying any top coats.

Safety Precautions and Proper Ventilation

When working with Rust-Oleum Rust Reformer, safety should always be your top priority. This product contains chemicals that can be harmful if inhaled or ingested, so it’s crucial to take necessary precautions; Always work in a well-ventilated area, ideally outdoors or in a garage with open doors and windows. Proper ventilation helps to prevent the build-up of fumes, reducing the risk of respiratory irritation or other health issues.

In addition to ventilation, it’s essential to wear appropriate personal protective equipment (PPE). This includes gloves to protect your skin from contact with the product, as Rust-Oleum can cause skin irritation. Eye protection, such as safety glasses or goggles, is also crucial to prevent splashes from entering your eyes. A respirator or mask is recommended, especially when spraying, to avoid inhaling fumes.

Keep Rust-Oleum Rust Reformer out of reach of children and pets. Store the product in a cool, dry place away from heat, sparks, and open flames. If swallowed, do not induce vomiting and seek immediate medical attention. Always read and follow the manufacturer’s safety instructions provided on the product label.

Clean-Up and Disposal of Materials

Proper clean-up after using Rust-Oleum Rust Reformer is essential for safety and environmental responsibility. Start by cleaning your application tools immediately after use. For brushes, use xylene or mineral spirits to remove any remaining product. Ensure that you clean the brushes thoroughly to prevent them from hardening and becoming unusable.

For spray equipment, follow the manufacturer’s instructions for cleaning. Typically, this involves flushing the sprayer with xylene or mineral spirits until the solvent runs clear. Always dispose of used solvents properly; never pour them down the drain or onto the ground. Instead, take them to a hazardous waste collection center or follow local regulations for disposal.

When disposing of empty Rust-Oleum Rust Reformer cans, ensure they are completely empty. Allow any remaining product to dry and harden before disposing of the can in accordance with local waste disposal guidelines. Check with your local authorities for specific instructions on how to dispose of paint cans and other hazardous materials.

Wipe up any spills immediately with a clean cloth and dispose of the cloth properly. By following these clean-up and disposal guidelines, you can minimize environmental impact and ensure a safe working environment.